PERFECTING THE SCIENCE OF UNIT SORTATION

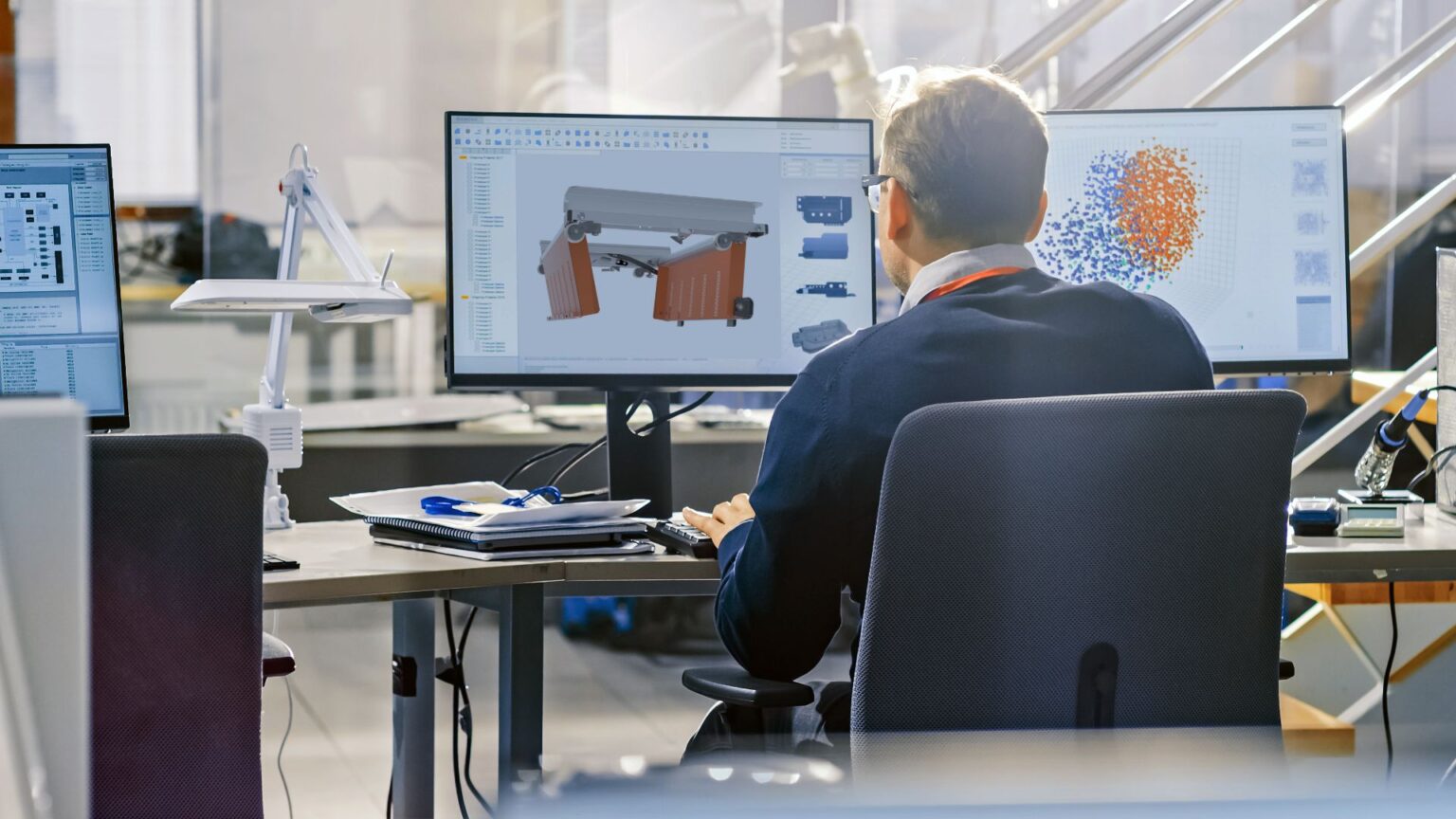

Our high-quality automated warehouse sortation systems are modular, simple, and robust. EuroSort solutions are proven to improve productivity, accuracy, and efficiency in distribution centers worldwide. We design and manufacture high-speed industrial sortation systems and use space-saving designs at a lower cost and smaller footprint than other automated sortation technology on the market.

Dynamic sortation applications

Whether you are looking to sort clothing, mail, or pharmaceutical bottles, our automated warehouse sorters can help improve your operations. Our systems are precision designed to improve the productivity and efficiency of companies in the following industries.

High speed unit sortation solutions

At EuroSort, we understand that your product mix changes over time depending on the season, the economy, or even just buyers tastes and your sorter needs to be able to handle that. From Apparel to Jewelry, Parcels to Electronics, there is a EuroSort unit sorter for it all.